Material Handling & Automation Equipment You Can Count On

Designed for You. Built to Solve.

30+ Years of Equipment Excellence

With over 30 years of experience, Kolinahr Systems delivers innovative automation and labeling solutions that drive performance, precision, and reliability in manufacturing.

Trusted by industry leaders, we engineer equipment that meets today’s production demands while anticipating tomorrow’s challenges.

Why Choose Kolinahr?

Reduce Downtime

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Increased Plant Efficiency

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Equipment that Lasts

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

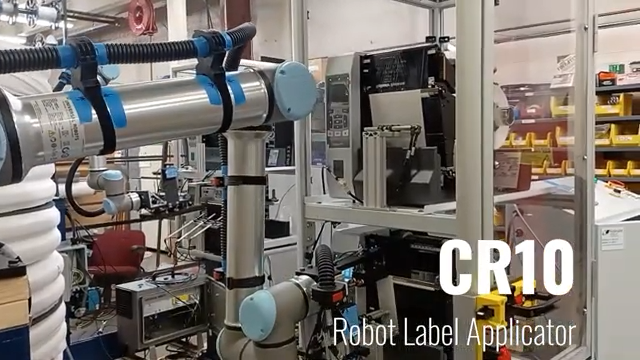

Our Top Products

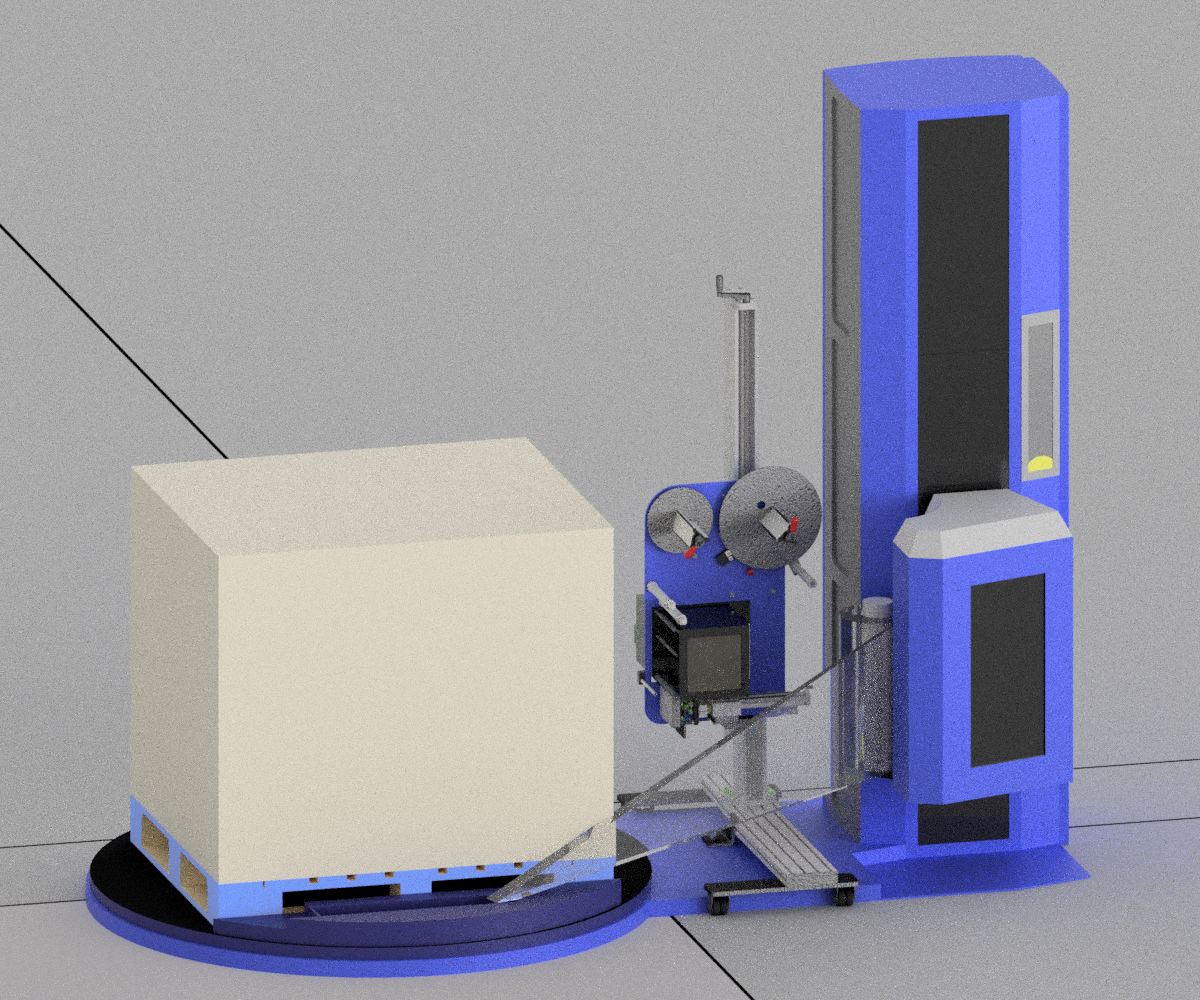

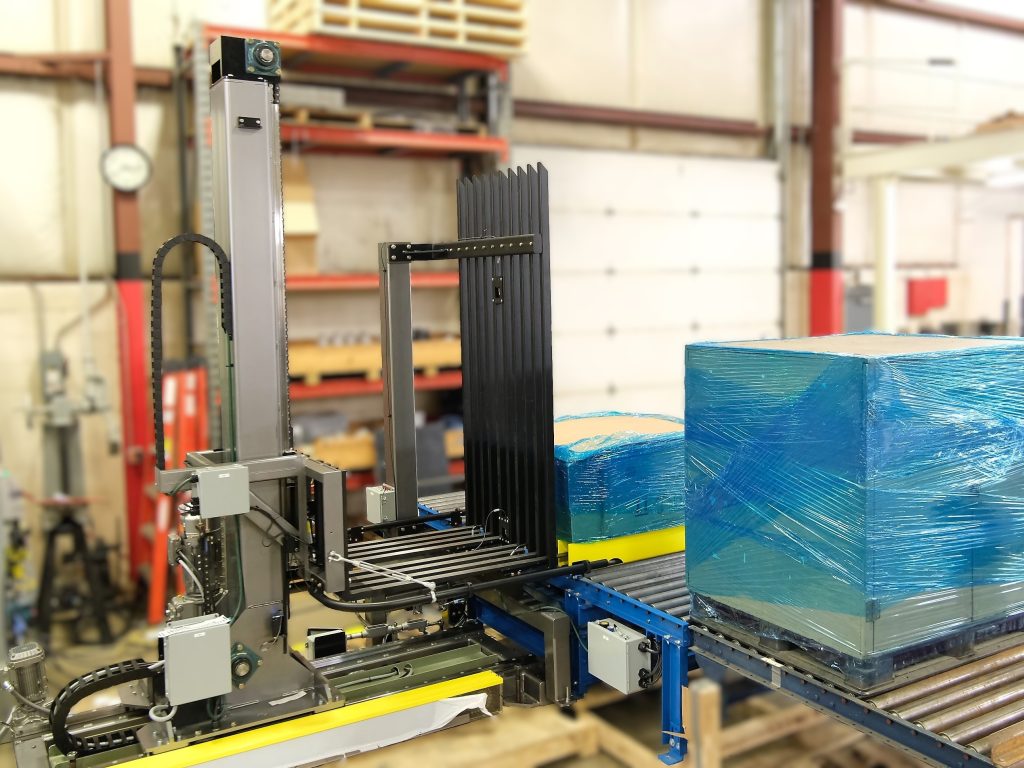

Pallet Label Applicators

Our pallet label applicators ensure accurate, secure labeling on every load, meeting industry compliance with speed and consistency.

Pallet & Load Stacking

Designed for stability and efficiency, our pallet load stackers optimize space and streamline your warehouse operations.

Case Labeling

Kolinahr’s case labeling systems deliver crisp, reliable identification on every package, enhancing traceability across your supply chain.

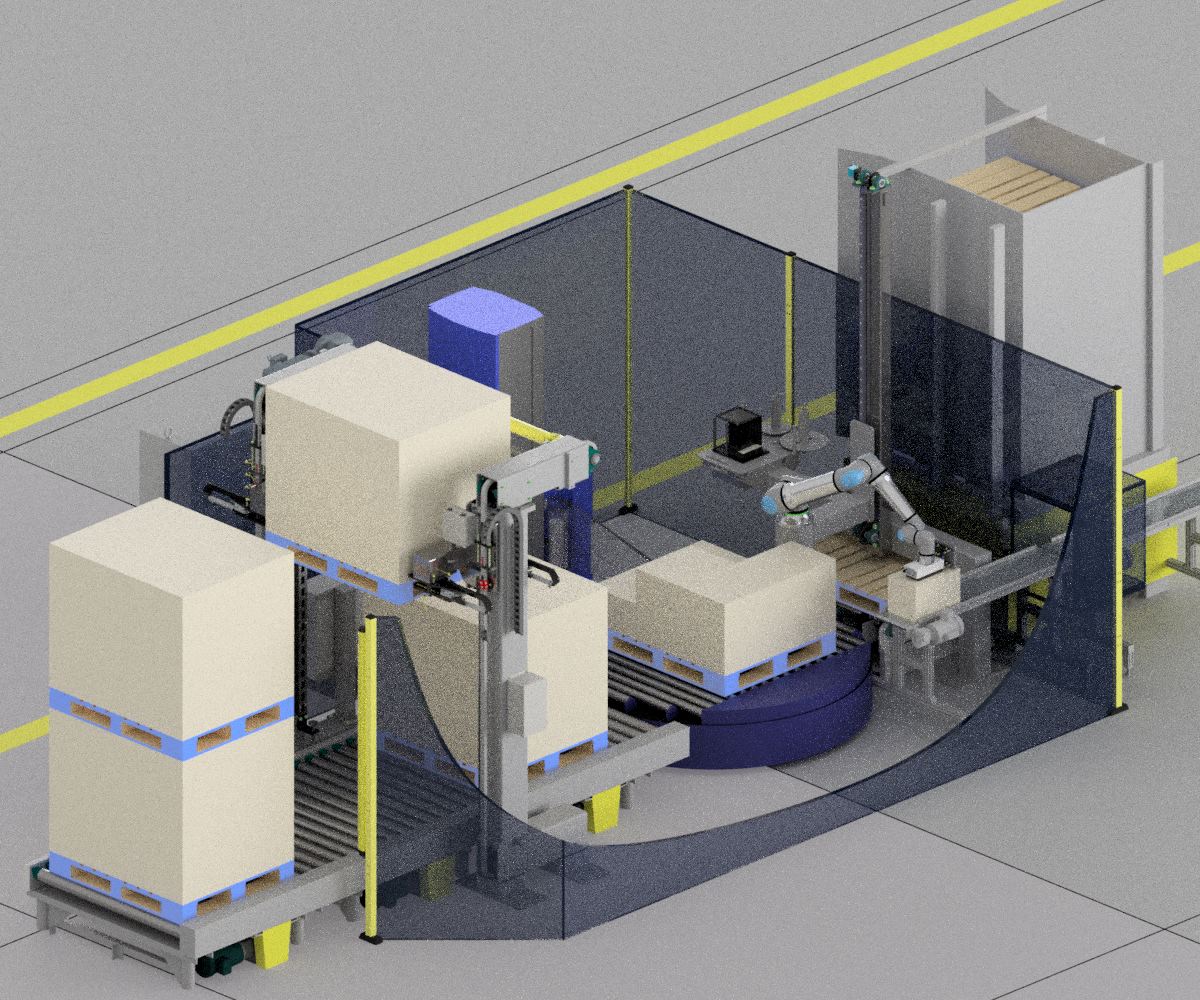

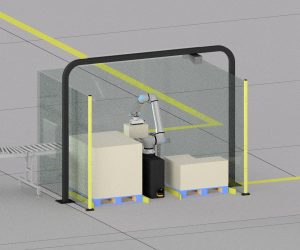

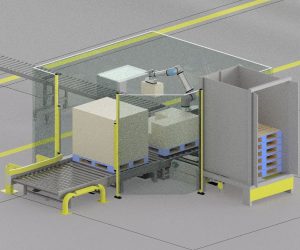

Robotic Palletizers

Our robotic palletizers automate stacking with precision, reducing labor costs while increasing throughput and workplace safety.

Industries We Serve

Food & Beverage

From packaging to production line automation, Kolinahr helps food and beverage manufacturers meet stringent safety standards while streamlining throughput.

Our systems improve batch traceability, reduce downtime, and optimize OEE—helping you deliver fresher products, faster.

Family Care

In the fast-paced world of family and personal care products, consistency and speed are critical.

Kolinahr enables better line synchronization, SKU flexibility, and real-time monitoring to reduce waste and meet shifting consumer demands without sacrificing quality.

Healthcare

Kolinahr supports medical manufacturers with systems that enhance compliance, precision, and documentation.

Our solutions help ensure product integrity, meet regulatory requirements, and drive process improvements across clean room environments and critical production lines.

Warehouse Distribution

Whether you’re handling complex assembly or high-volume packaging, Kolinahr brings visibility and control to distribution-focused operations.

From warehouse labeling to performance analytics, we help streamline processes across the entire supply chain to reduce delays and cut operational costs.

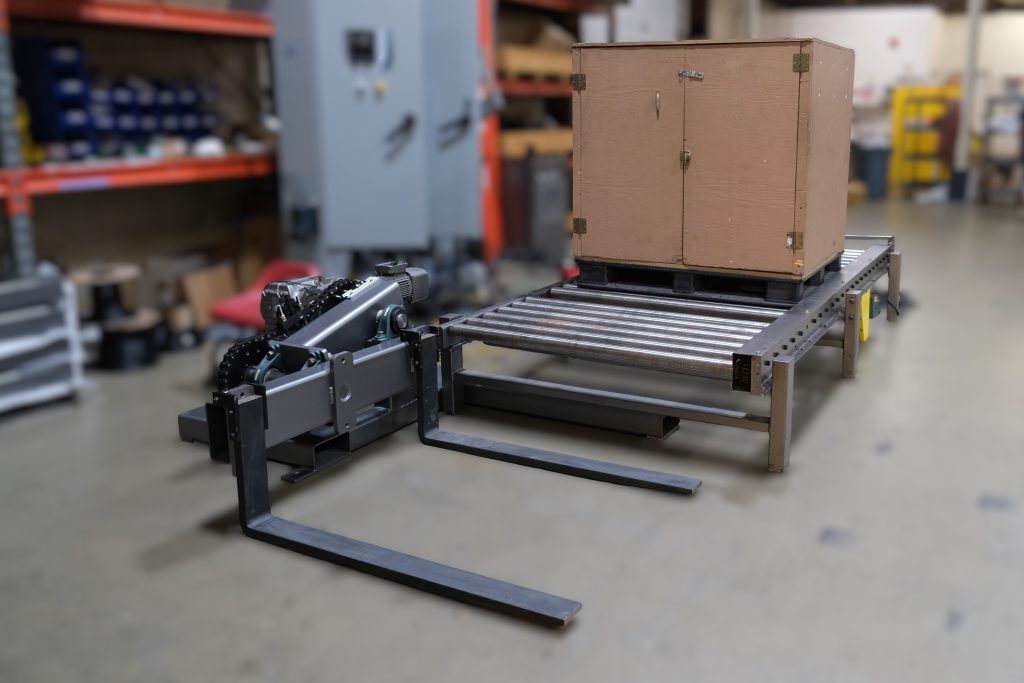

Introducing the PLS200 Pallet

Lift System

The PLS200 is a pallet lift system designed to take pallets from floor level to conveyor level (or from conveyor level to floor level), minimizing damage to fork trucks.

Unlike other pallet lift designs on the market, this machine does not require a pit to be dug for installation, or messy hydraulics that need to be maintained.

Other Product Videos

Playlist

1:05

0:55

1:58

1:17

0:24

Custom Solutions

Tailored Technology. Real Results.

At Kolinahr Systems, we design custom automation solutions that align with your unique production needs to deliver measurable efficiency gains.

Built for Your Process

Whether it’s labeling, material handling, or legacy system integration, our team creates solutions tailored to your workflow.

From Concept to Commissioning

We manage everything from discovery to installation, ensuring your solution is scalable, reliable, and ready for growth.

Integration Expertise

Our custom systems integrate seamlessly with your MES, ERP, and PLCs to enhance visibility and operational performance.

In the Words of Our Customers

Case Studies

Featured News

Explore the Future of Labeling

Custom Solutions Built Around Your Needs

While every Kolinahr machine is custom-built to meet the specific needs of your facility, some projects call for something truly unique. That’s where we thrive.

Our experienced team of engineers specializes in tackling complex challenges with creative, outside-the-box solutions—no matter how big, small, or unconventional the problem. If you need it built, we’ll find a way to make it happen.

Contact Us Today

Let’s Talk About Your

Automation Needs

Ready to improve efficiency and performance on your production line? Fill out the form below, and a Kolinahr Systems expert will get in touch to discuss the right solution for your operation.