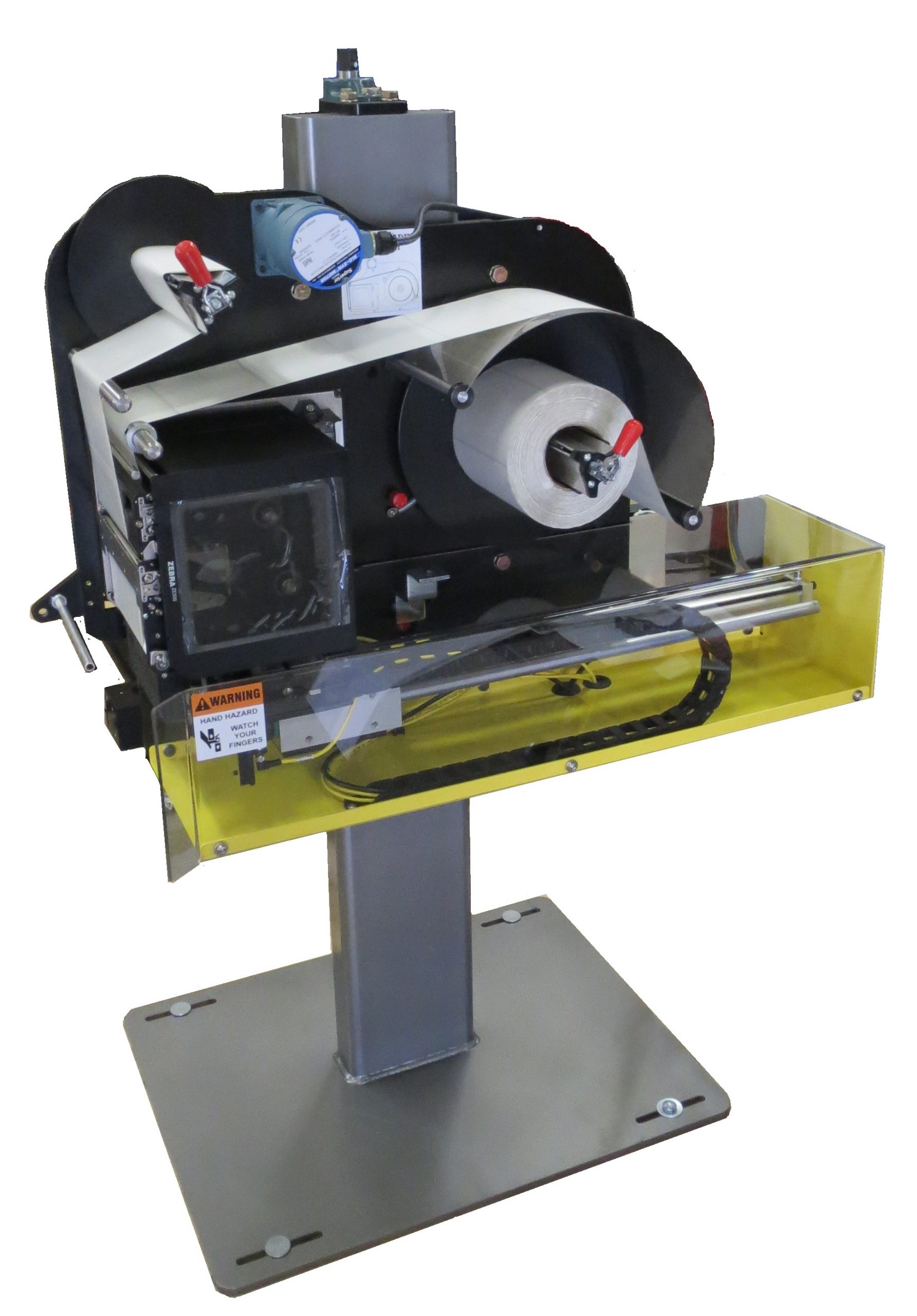

SA1000: AUTOMATIC PALLET LABEL APPLICATOR

maximum control

The SA1000 Automatic Pallet Label Applicator is designed to print and apply labels to the side of a pallet load. The machine is controlled by a PLC, which can communicate with the conveyor, stretch wrapper, and palletizer to ensure proper product handling during the labeling sequence. Optional full diagnostic reports and communication tracking make troubleshooting easy. A PC program simplifies the process of managing the label format and database.

Accurate & Consistent Label Placement

Barcode labels are printed using a Zebra ZE500 print engine and are applied to the pallet load by a 24-in (61cm) variable stroke slide cylinder tamp assembly. The spring-loaded tamp-pad adapts to the pallet load surface.

Built to Last

The rugged PHD slide-cylinder, heavy duty stand, UL listed NEMA 12 industrial controls enclosure, and other high quality parts help ensure that the SA1000 will handle the rigors of 24/7 pallet load labeling.

SA1010 Auto-Height Option

The Auto-Height Option allows customers to label stacked loads. The label applicator searches and finds either the bottom or top of each load and places the label in a consistent location on each of the stacked unit loads.

This configuration can also be used to send loads with multiple different heights through the same machine. The label applicator finds the top of the load and then places the label at a consistent height from the top.

Options

Our team works to create a solution to fulfill your facility’s packaging needs. Therefore each machine is custom built for your application. Here are a few added features our customers have opted to include, but if you don’t see what you need, please contact us to speak with an engineer.

-

-

- Low label stock and ribbon sensors

- Operator lock-out for printer maintenance

- Separate control panel for installation outside of fencing

- End of arm barcode scan and verification equipment

- TrakSYS tracking software

- And more…

-