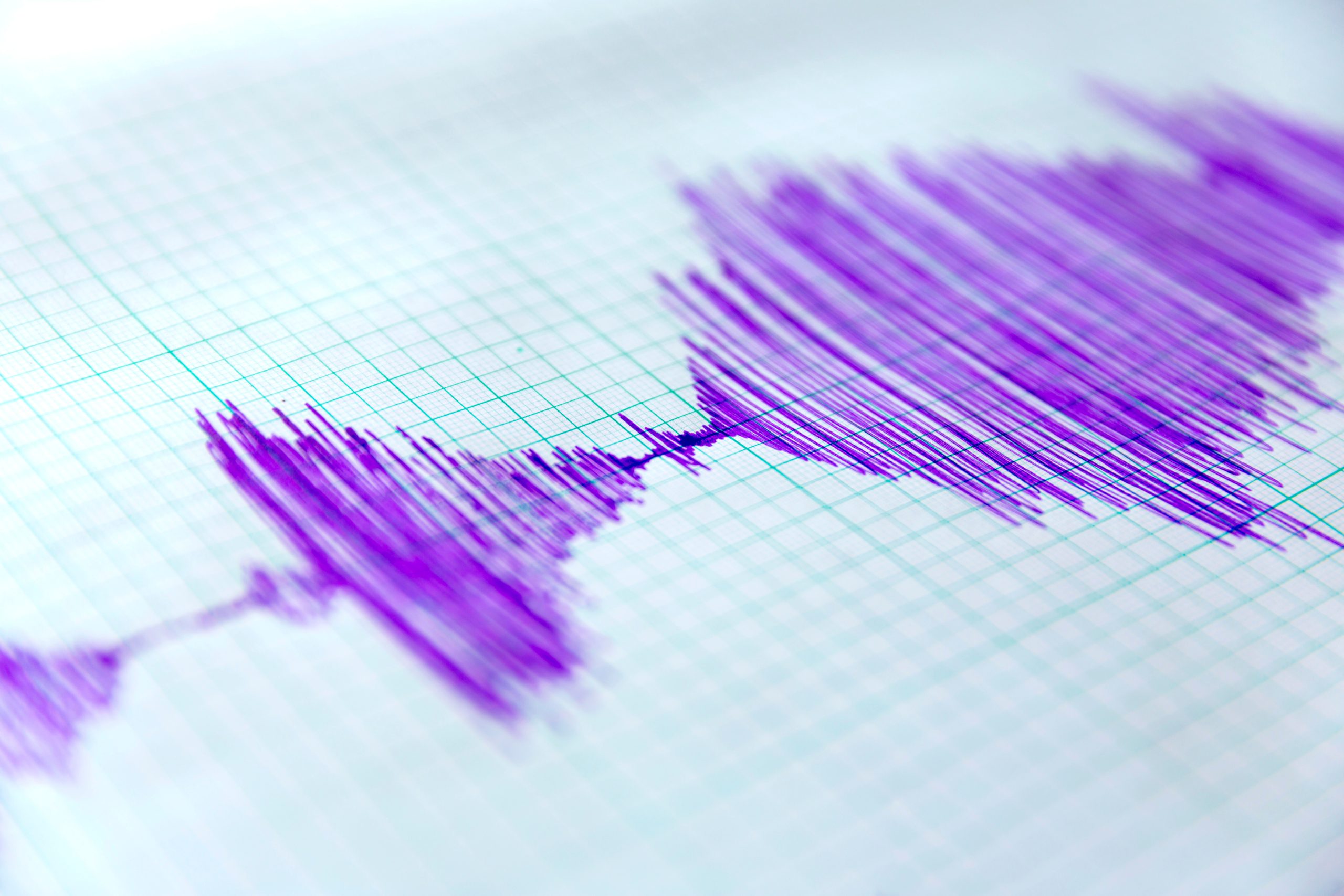

THE COST OF NATURE

The USGS and FEMA, in a 2023 study, estimated that seismic activity costs the United States an average $14.7 billion in building damages and associated losses annually. California alone makes up over half of that estimate.

BUILDING CODES

Today, most communities have adopted the International Codes (I-Codes) as published by the International Code Council with input from professional engineering and academic institutions. Building codes are a set of requirements adopted both regionally and nationally to regulate the design, construction, renovation, and maintenance of structures. Within these codes are seismic design regulations. They set the minimum standards to protect the health and safety of the occupants and the integrity of the building. In the United States you can check your seismic design categories here.

INVESTING IN SEISMIC SAFETY

Building codes often have seismic certification requirements for certain critical or life-safety related components. Even if your regional building codes don’t require it, there are several reasons to consider purchasing seismically rated manufacturing equipment as well if you are in an active earthquake zone.

1. SAFETY

Equipment that fails in an earthquake could cause harm to people, other equipment and infrastructure.

2. DOWNTIME

Damaged equipment will cause longer production disruptions as you try to get back up and running. This could open a window for your competitors to acquire some of your market share.

3. RESILIENCE

If it can withstand an earthquake, it can certainly withstand the abuse of a rigorous 24/7 production schedule.

METHODS OF SEISMIC CERTIFICATION

There are two main methods of testing equipment and issuing seismic certification. The first method is through shake table testing. Shake tables simulate the movements of an earthquake. Equipment can be placed on top of the table and then operators dial in different types and intensities of earthquakes. After the simulated earthquake the equipment is then evaluated to see how if performed. The second method and the one that we use here at Kolinahr is through computer modeling. Engineers us a combination of modeling software and experience to determine how the equipment would react in earthquakes of varying types and magnitudes. This method is great for equipment that is too large for the shake table or difficult to transport.

WHAT DOES CERTIFICATION MEAN

A seismic certification means that the equipment will withstand and continue to function after an earthquake of the designated magnitude. At Kolinahr, many of our pallet load stackers have been certified by an independent approved agency. Each of these machines has been determined to be capable of withstanding an 8.0 magnitude earthquake.